Analyze Plant Data from Anywhere

The Hub for Process Analytics allows you to analyze machine data from anywhere in the world. Know when a machine starts making suspect parts, so you can diagnose the issue remotely and start making good parts again fast—that means less scrap, less downtime, and higher quality parts.

Access Real-Time Data from Anywhere

Access real-time data from all of your machines in one place from anywhere in the world. Stop worrying about what’s happening on the plant floor while you’re away—instantly know which machines are running, down, and producing reject parts.

Build and Export Reports

See data that is important to you in customizable reports. Sort, filter, and move data around to see historical trends and reoccurring problems. Export to a shareable format to prove your processes and reduce liability.

View Job Audit Reports

Stop manually auditing processes and enjoy automated job audit reports that you can access at any time during or after a run. Initial and ending alarm limits, changes and events tell you how many reject parts occurred and if anyone changed the alarm limits during a run.

Review and Replay Historical Data

Replay cycle graphs from any time in history to prove processes, see trends over time, and see where processes were adjusted. Zoom into specific points in a single shot, or zoom out to view all data overtime.

Get to Know Your Top Five

Quickly see which machines produce the greatest percentage of reject cycles, longest down time, most alarms, most cycles, and more. This will help direct efforts to machines that cause the most issues and can help pinpoint problems to prevent future occurrences.

Features:

The Hub for Process Analytics allows you to analyze machine data from anywhere in the world. Know when a machine starts making suspect parts, so you can diagnose the issue remotely and start making good parts again fast—that means less scrap, less downtime, and higher quality parts.

Access Real-Time Data from Anywhere

Access real-time data from all of your machines in one place from anywhere in the world. Stop worrying about what’s happening on the plant floor while you’re away—instantly know which machines are running, down, and producing reject parts.

Build and Export Reports

See data that is important to you in customizable reports. Sort, filter, and move data around to see historical trends and reoccurring problems. Export to a shareable format to prove your processes and reduce liability.

View Job Audit Reports

Stop manually auditing processes and enjoy automated job audit reports that you can access at any time during or after a run. Initial and ending alarm limits, changes and events tell you how many reject parts occurred and if anyone changed the alarm limits during a run.

Review and Replay Historical Data

Replay cycle graphs from any time in history to prove processes, see trends over time, and see where processes were adjusted. Zoom into specific points in a single shot, or zoom out to view all data overtime.

Get to Know Your Top Five

Quickly see which machines produce the greatest percentage of reject cycles, longest down time, most alarms, most cycles, and more. This will help direct efforts to machines that cause the most issues and can help pinpoint problems to prevent future occurrences.

Features:

- Access process data and statistics

- Export audit reports for process changes

- Review and replay historical data

- View plant-wide summary reports

- Customize plant overview dashboards

- Quickly diagnose new or trending processing problems

- Lower liability

- Reduce scrap and machine downtime

- Produce higher quality parts

- Stop wondering what processing changes were made

Launch Molds Faster and Easier

We so often need to put molds into any available machine due to tight production deadlines. However, putting the wrong mold in the wrong machine can lead to poor part quality, inefficient processes, or even tool damage. The Hub allows you to easily transfer molds by automatically generating machine-specific setup sheets, recommending compatible machines, and providing a database to store and share documents.

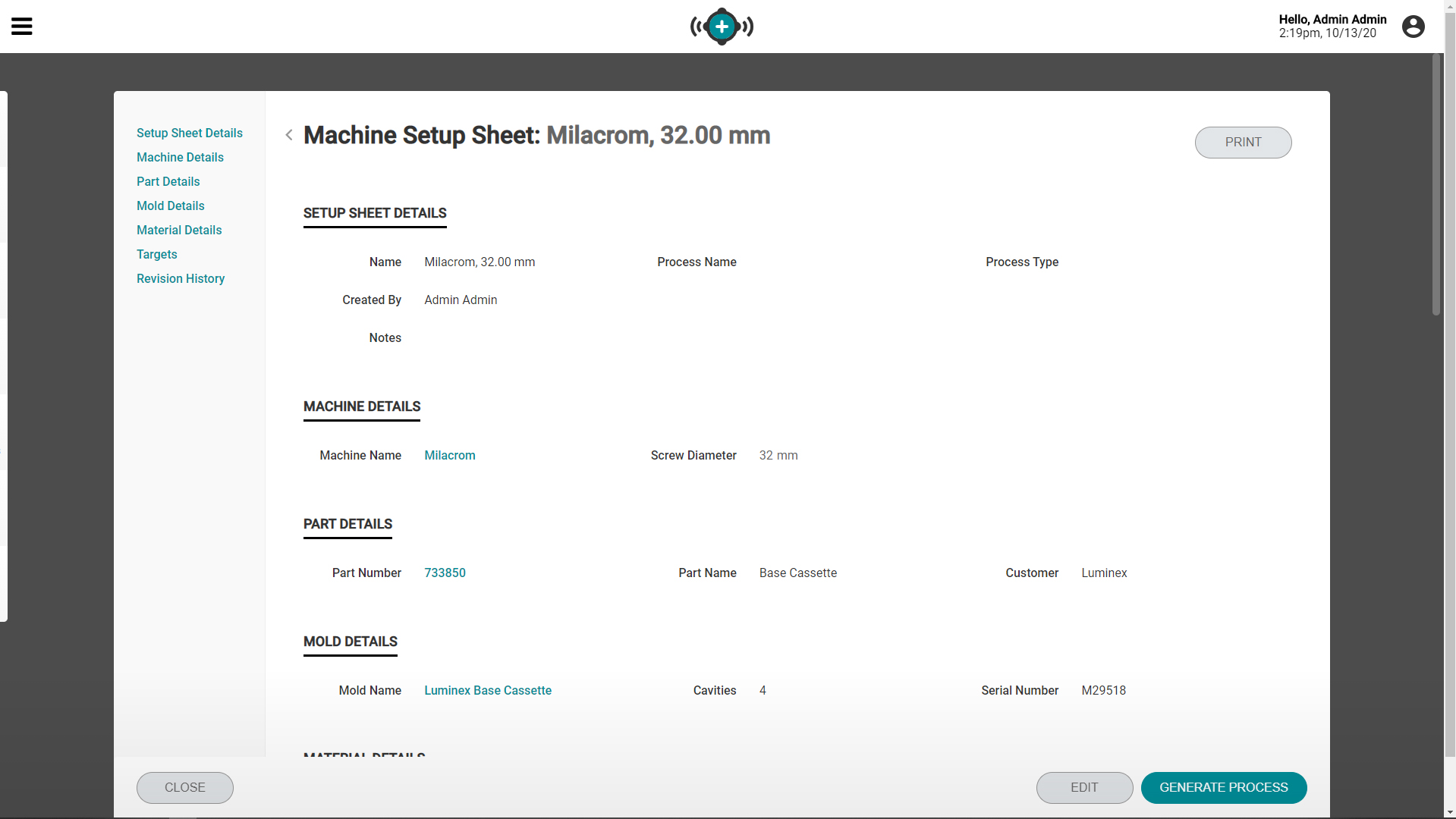

Automatically Generate Machine-Specific Setup Sheets

Mold transfers and revalidation can be extremely expensive and time consuming. What if we told you that you never had to revalidate a mold again? Through the use of Machine Independent Variables (MIV) and automated machine-specific setup sheets, you are able to transfer any mold to any capable machine.

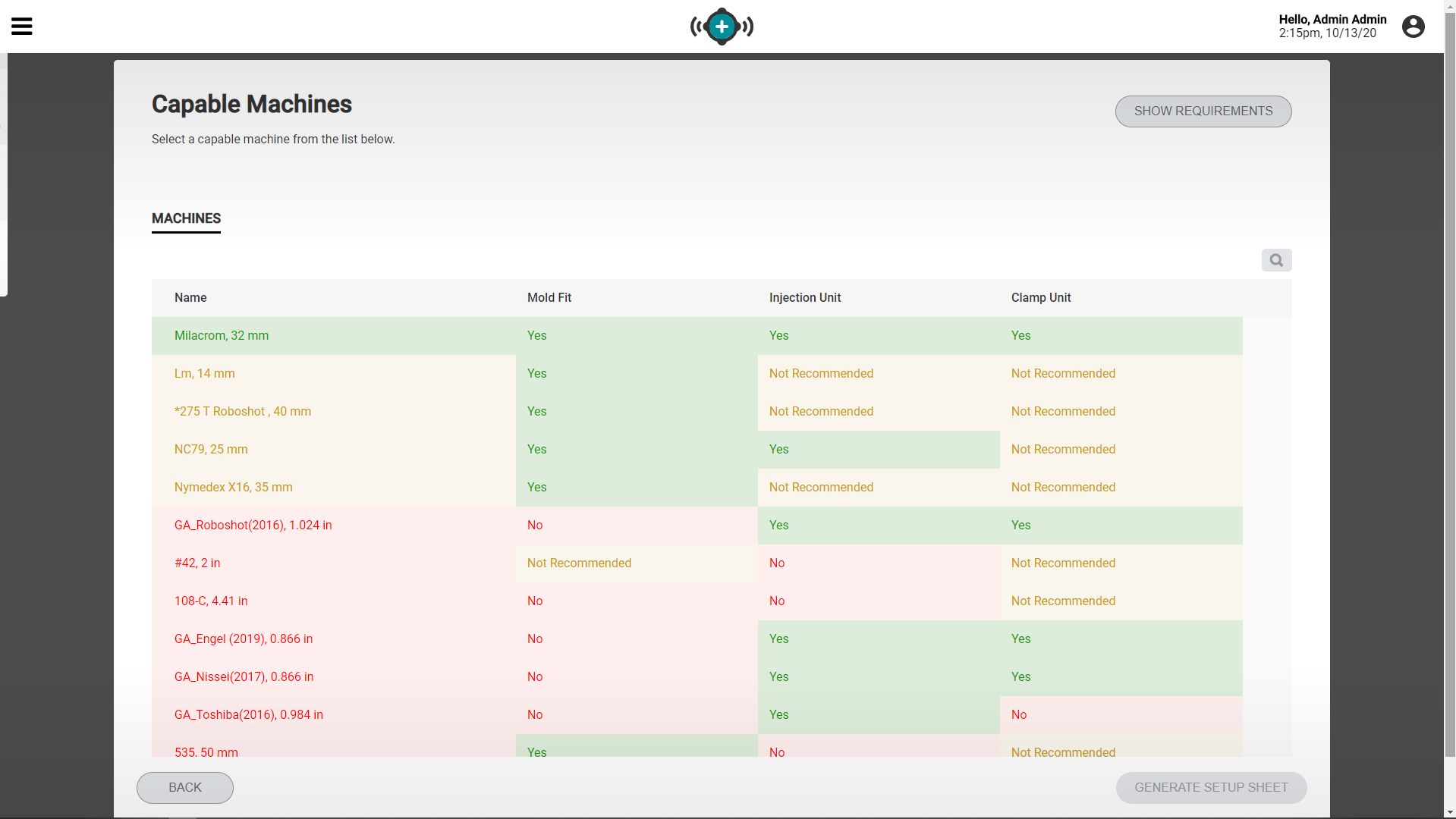

Know Which Machines Can Efficiently Run Each Mold

To ensure the proper fit, The Hub generates a list of recommended machines for each mold. This shows you which machines molds will physically fit in and which will provide optimum process capabilities. Clear red and green highlights allow you to quickly and easily view available, compatible machines.

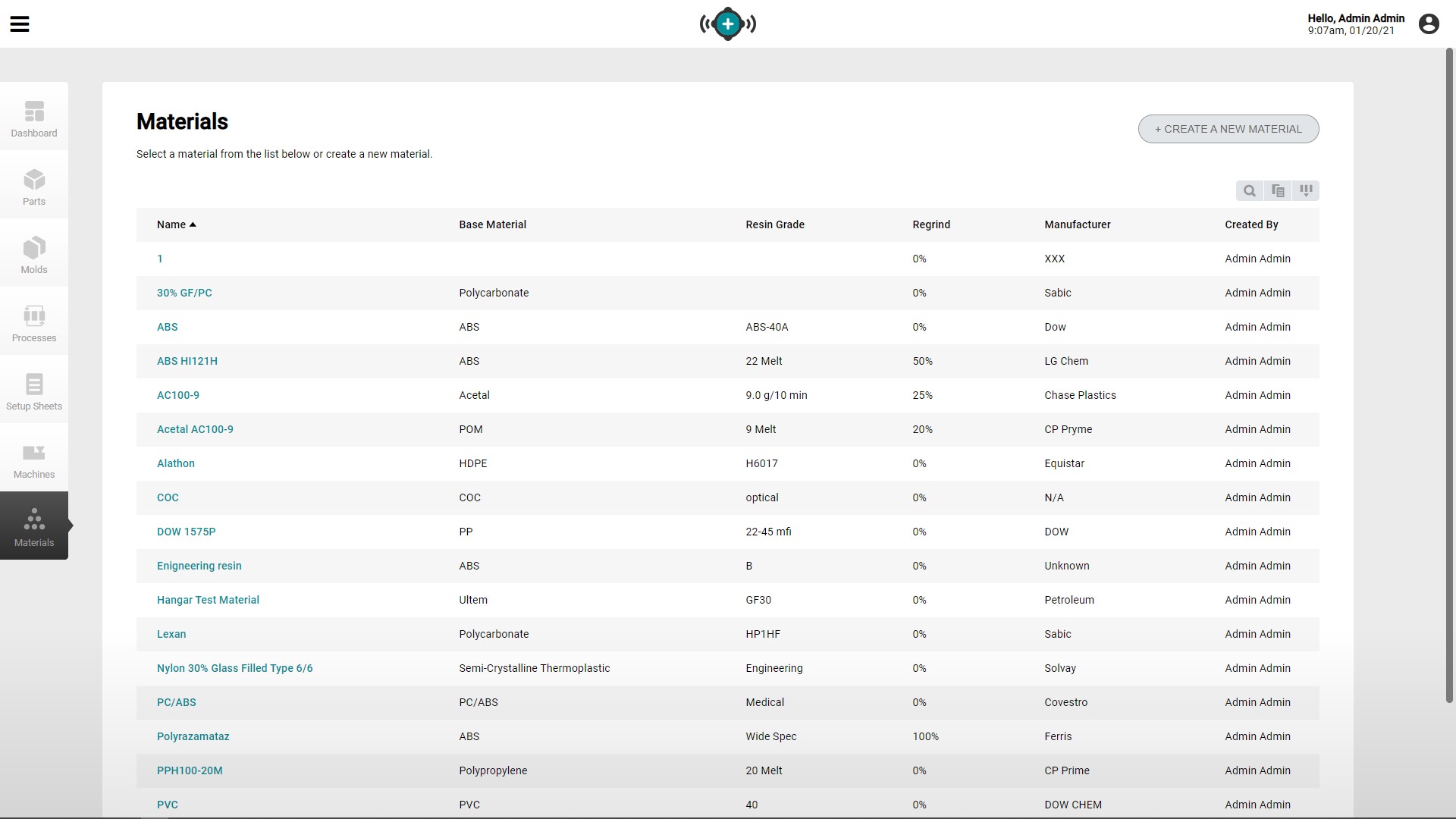

Access All Facility Assets from One Place

The Facility Asset Database allows you to store and share documents across your organization. You’re able to access information about your machines, molds, parts, and materials from a single user interface, further improving overall efficiency.

Features:

- Facility asset database for machines, molds, parts, and materials

- Mold match recommendations for fit and capability

- Universal process sheet database

- Machine specific setup sheet database

- Automatically-generated, machine-specific setup sheets

Benefits:

- Reduce the risk of tool or machine damage

- Get to market faster with less waste

- Make good parts from the first shot—no more trial and error testing

- Build an audit trail with revision history

- Access documents from anywhere

Get to Market Faster

Starting at the design process allows you to catch risks of molding deficiencies upfront before the steel is cut. Simulation Support allows you to import simulation files into The Hub database and automatically generate universal process sheets.

That means a significant time savings during a tool launch—you can go from concept to virtual process without cutting steel. No more rework or spending weeks establishing and testing processes. Just plug and play.

Simple, efficient, cost effective. Plus you get to market faster, and we all know time is money.

Features:

- Perform mold and machine compatibility analysis based on simulation inputs

- Automatically populate mold and universal process parameters

- Convert simulation-predicted processes to machine-specific setup sheets

- Utilize Moldex3D® and Autodesk Moldflow InSight® file database

Benefits:

- Accelerate process development by rehearsing tool launches in a virtual environment

- Minimize hassle, time, and waste with mold transfer flexibility and upfront equipment preparation

- Optimize mold and process engineering taking into consideration the capabilities of multiple machines

- Improve collaboration between simulation analyzers and manufacturing professionals