Tip of the Day 112: How to NOT Puncture Your Fill-Only Parts

When setting up decoupled processes you generally need to make a fill-only part. If the process is up and running and needs to be checked you can set the machine controls to make a fill-only part to see if it is the same as it was when you first set up the process.

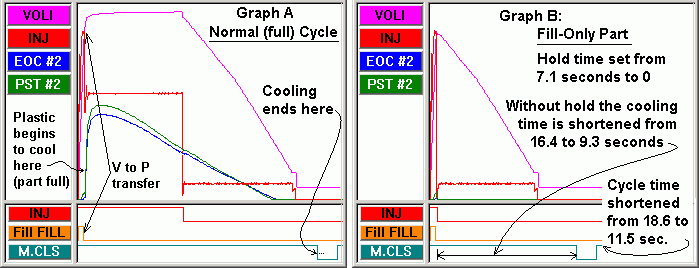

To make a fill-only part force the machine to stop filling at the point where the machine is switching from fill to pack (V -> P in decoupled II, V1 -> V2 in decoupled III) (graph A below). This means forcing the press to transfer at the end of the machine fill point and turning off hold. This is where the puncture problem occurs, among others.

To make a fill-only part on many machines you need to set the hold time* to zero (or a very small value) in order to get rid of all of the hold pressure. The machine’s „cooling time“ starts at the end of hold. So removing the hold time and not adjusting the cooling time shortens the cycle. This can allow the part to be ejected before it is cool enough to withstand ejection force (graph B below). When this happens your part will be perforated and possibly hang up in the mold or not eject at all.

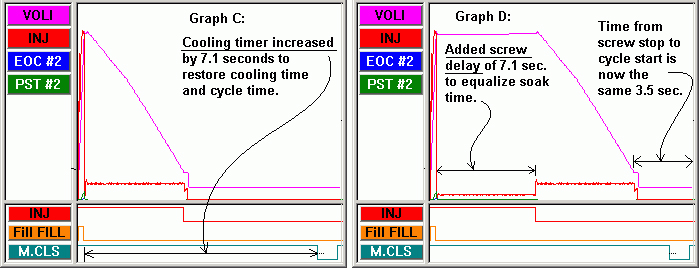

In order to make a fill-only part with the same cycle time you first need to know whether your machine has a mold clamped timer or a post-hold „cooling“ timer. If it is the latter then add to the cooling timer the time you have subtracted from the hold timer (graph C). Furthermore, if you want the same residence (soak) time for the material mixed in front of the screw then you also need to add screw delay equal to the subtracted hold time. (graph D).

In addition to preventing punctured parts, increasing the cooling timer when subtracting hold time will keep the cycle time constant. Thus the mold surface will run at approximately the same temperature that it does on normal cycles instead of heating up with short cycles. Keeping the cycle time and mold surface temperature constant ensures that the fill-only parts contain approximately the same material as they do at fill-to-pack time when the normal cycle is running (with hold).

Moral:

To make fill-only parts you must know your machine controls

Control settings for fill-only parts cause different effects on different machines.

*Some machines have an overall injection timer instead of a hold timer. If you shorten this to eliminate hold pressure be careful that it is no shorter than the fill time for the fill-only part. If it is set too short it can give you a false fill-only part because it will transfer the machine before the machine reaches the fill position used in the normal cycle.