Tip of the Day 108: Will the eDART’s V-P Actually Control Transfer?

When setting up the eDART™ system to supply an external transfer signal there is some danger to the mold if the transfer output fires but the machine does not recognize it. Here is a tip for ensuring that it is working before you turn control over to the eDART.

Test of Signal

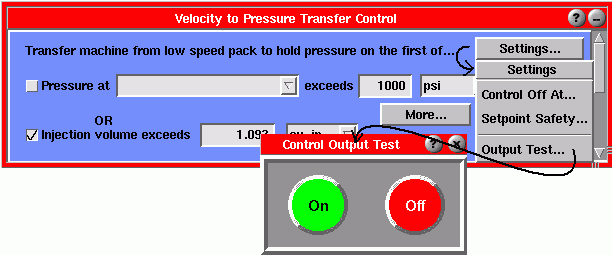

First, the „V to P Transfer“ tool on the eDART has a „Test“ button on the „Settings“ menu.

You can select this item, press the on and off buttons and check the press controller’s diagnostic page for changes in the input. The eDART does not allow you to manipulate the test button when the press is cycling.

Test of Function

However this only tells you if the input is going into the machine. It does not tell you whether the machine software will listen to it or when. To be absolutely sure that it the V->P will transfer here is a suggestion.

-

-

Set up a process (D2 or D3) with transfer to hold on the machine’s screw position.

-

-

-

Make sure the process ends with almost no cushion, probably bottoming out shortly after transfer. This will avoid mold damage if the transfer does not work.

-

-

-

Make a template.

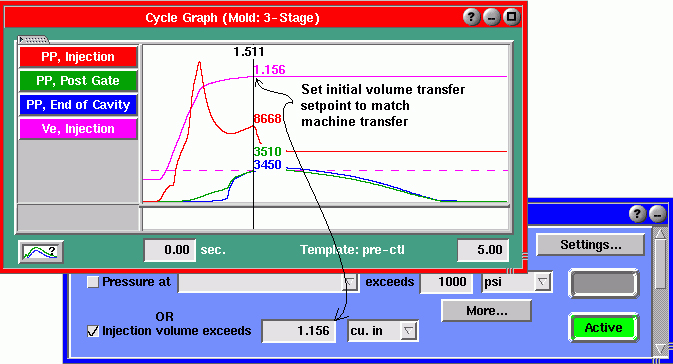

Place the cursor on the eDART’s Cycle Graph slightly before the place where you see the machine dropping into hold.

-

-

-

Read the volume number from the cursor and put it in the V->P transfer tool’s volume control, enabling the control.

-

-

- Enable the machine’s external transfer. Some machines allow both external and internal and some force you to use one or the other.

-

- The V->P volume switchover should show „Active“ and the machine should transfer earlier as shown below.

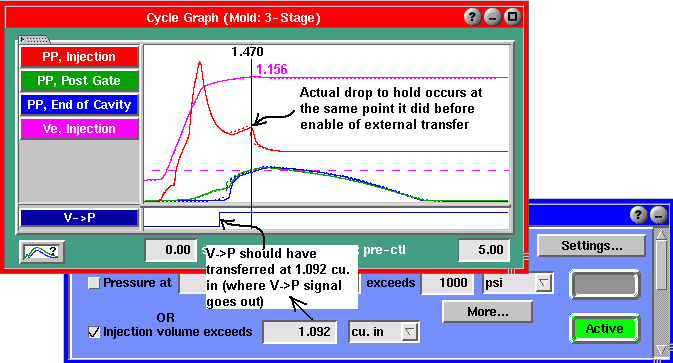

You should be able to move the transfer point around at will by changing the volume number in the eDART’s V->P tool. If the curve does not change from the template (as shown below) then the machine is not accepting the transfer signal from the eDART.

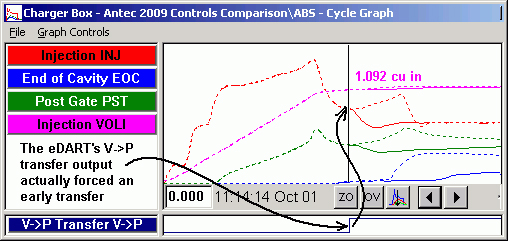

Here is an example in which the machine did change its transfer on the signal from the eDART. Therefore the external transfer is working.

- The V->P volume switchover should show „Active“ and the machine should transfer earlier as shown below.

-

- Once you are sure that the eDART’s V->P will transfer the machine (early, as above) then you can turn on cavity pressure control, add shot size as needed for cushion and increase the V->P transfer volume number as a backup.

-

- The machine may have the input but not the proper software installed.

-

- It may have an „enable“ position, injection pressure or time where it will not look for the external V->P until the enable position is reached.

-

- The V->P may be wired incorrectly. For example one machine wiring guy thought the OR2-D would supply a 24V signal to the machine. He did not know he needed to „power“ it.

-

- The machine doesn’t like you.

You can put the Control Output / V->P Transfer on the Sequence traces on the cycle graph to see when the eDART is actually sending the V->P signal. For machines that transfer on a 0-10V analog signal you can put this signal (Plastic Pressure Output / V->P Transfer) on the cycle graph’s main pane (with the other curves).