Injection pressure is a crucial parameter in the process of injection molding. Injection pressure builds by the force of the injection unit and the area of the screw pushing molten plastic into the mold cavity. The injection pressure is typically measured in pounds per square inch (psi) or bars (1 bar = 14.5 psi). It is one of the most important factors that determine the quality and consistency of the final product.

The injection pressure required for a particular application depends on various factors such as the type of plastic material, the size and shape of the product, and the design of the mold. In general, the injection pressure should be high enough to fill the mold cavity completely without causing any defects or voids in the finished product. At the same time, it should not be so high that it causes the mold to break or the plastic to degrade.

Fill Pressure , Pack Pressure, and Hold Pressure

The fill pressure along with the pack and hold pressures are present in the molding process. The fill pressure is the pressure required to fill the mold to a certain level (95 to 98% of part volume). The pack pressure is the pressure applied after the mold is filled. It’s required to pack the plastic into all the corners and crevices of the mold cavity. Hold pressure is the pressure applied during the plastic cooling phase to ensure that the plastic remains in contact with the mold surfaces and to minimize/control shrinkage on the part. Higher fill pressures, as a result of high fill speeds, can help to improve the effect of packing and holding pressures of the part, which in turn can result in higher-quality finished products.

How to Calculate Injection Pressure

Injection Pressure as a concept is any pressure built up when the screw is pushing plastic forward towards the mold (fill, pack or hold). Injection pressure is the variable that provides some of the most vital information we need to understand and adjust the process as necessary. Injection pressure is determined by a simple equation:

P=F/A

Where: P=Pressure, F=Force, and A=Area.

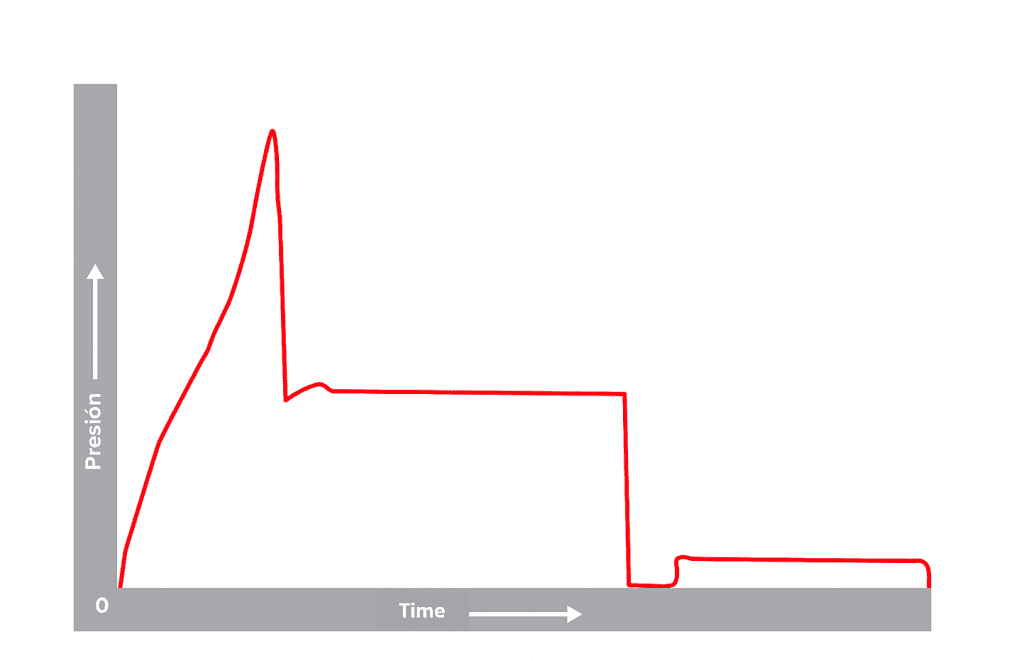

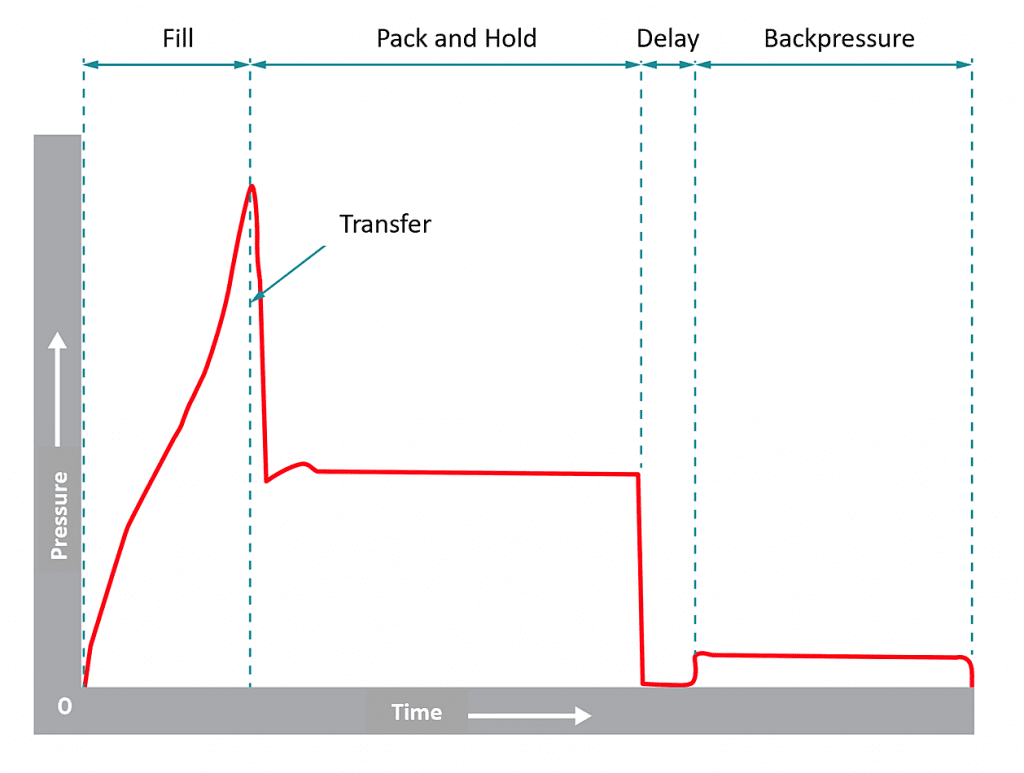

Think about the formula like this: pressure is the result of a force being distributed across a determined area. For the purpose of injection molding, we can add this: pressure is the result of a force being distributed across a determined area at a specific time. We add the variable time to this definition because injection pressure is applied within specific time periods during a cycle. We can look at the amount of pressure being applied over time on a pressure vs time graph, as shown below.

This graph represents the injection pressure behavior during a molding cycle and allows us to identify different stages within the cycle: Fill, Transfer Time, Pack and Hold, Screw Rotation Delay, and Screw Rotation Phase (Back Pressure). Each of these stages within the cycle are limited by a perfectly defined time slot as shown below.

So where does the injection pressure actually occur on a machine? That varies by machine type. For hydraulic machines, injection pressure occurs in the injection cylinder. For electric machines, it occurs in front of the plasticizing screw.

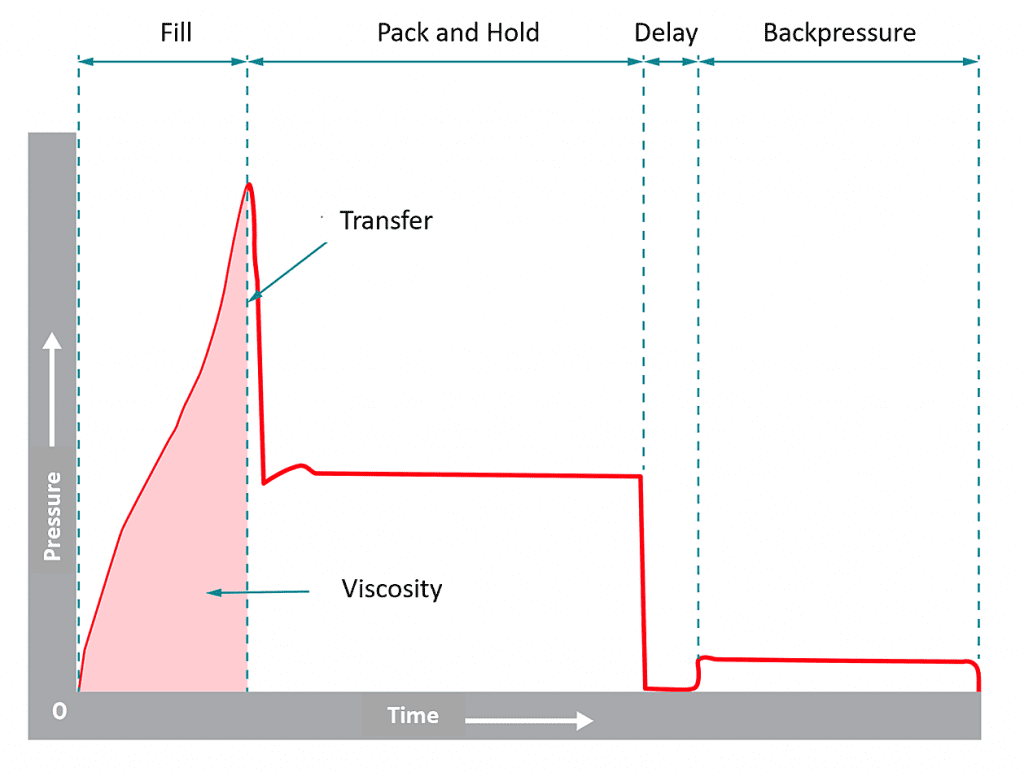

Accounting for Viscosity Shifts

The goal for any molder is to create a stable and consistent process, resulting in repeatable, good quality plastic parts. That’s pretty obvious, right? However, the reality is that often isn’t the case. With so many variables influencing every shot, it’s no wonder the graph curves often don’t match against each other shot after shot. Material, process parameters, mold, and machine conditions that aren’t well-defined are causes that create defective parts.Material condition and its viscosity are the most common variables that cause inconsistent quality. This viscosity shift can vary greatly from one production run to another, or even within the same production run. The injection pressure curve allows us to visualize this viscosity shift and act accordingly to account for it. If we’re looking at a graph, we can see the material viscosity represented as the area under the curve during fill stage, as shown below.

The area under the curve can be calculated digitally using the appropriate tools in the process. If that’s not an option, then you can gain a basic comparison of fill time vs pressure at transfer to understand material changes and adjust for them. If viscosity shifts, the injection pressure curve shape will change during fill stage. If that’s not accounted for, then the quality will likely be impacted, leading to scrap parts.

Conclusion

In conclusion, injection pressure is a critical parameter in the injection molding process that affects the quality and consistency of the final product. It is determined by various factors such as the type of plastic material, machine condition, the size and shape of the product, and the design of the mold. The injection pressure should be high enough to fill the mold cavity completely without causing any defects or voids in the finished product, but not so high that it causes the mold to break or the plastic to degrade. Careful monitoring and control of injection pressure are essential to achieve consistent and high-quality finished products. The injection pressure curve reveals a lot more information as well that we will unpack in future blog posts. Stay tuned!