Tip of the Day 71: Simple Text

The Setup Notes tool on the eDART can be a significant aid to process stabilization: ensuring that Knowing the structure defined by Job Setup helps to understand how the Setup Notes tool on the eDART works.

You can “attach” the Setup Notes tool from the Architect’s “Applications” tab to a mold. We recommend that if you are going to use it throughout the plant that you drag it to the “Molds” folder under the Architect’s “System” tab. That way it will start for all molds.

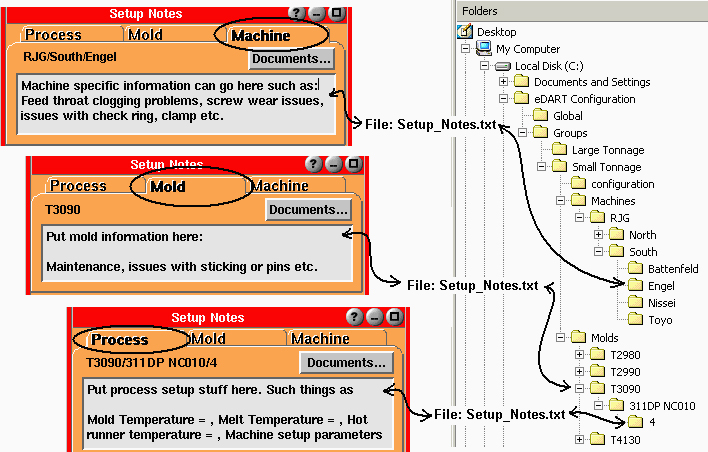

You can type text into the box on the setup notes tool. When you hit the “Accept and Save” button the Setup Notes tool saves that text in a file called “Setup Notes.txt”. The cross-copy service sends it up to the server under the folder structure shown at the right. You can also create “Setup_Notes.txt” files on the server and place them in the folders to which they apply. There is actually a different Setup_Notes.txt file for each tab on the tool. Be sure to name the file Setup_Notes.txt with the proper case and underscore as shown.

Any changes made on the server will be copied to the eDARTs (only on job start in semi-auto mold). Any changes made on the eDART will be copied to the server for distribution to other machines in the group. Note that the Setup_Notes.txt file must be a simple text file and not a Word or other complex word processing document. They should be created and edited with Notepad or Wordpad.

Next tip: Part 2: Complex Documents under the “Documents” button

Examples

“Process”

Put the setup parameters for the combination of mold, material and cavity layout into the Setup Notes tool on the Process tab. Each time a job is started the technician can read the notes and set the proper temperatures and machine parameters.

If you have not entered a material or cavities on the Job Setup window then the “Process” tab notes will be the same as the “Mold” tab.

Mold

A mold may have some specific information about plumbing or maintenance or some sort of core operation. Anything related to the tool itself can go under the “Mold” tab and will appear regardless of what material or cavity layout is running.

Machine

Some machines have odd behavior that you may want to note under the “Machine” tab. Someone may leave notes about the last time a screw or filter was changed.