Tip of the Day 68: Multiple Sorting Outputs on the eDART – Part 1

Many people know that this feature exists but know neither what it is for nor how to activate it.

The Problem:

In some molding applications it is wise to have a different sorting output for each cavity. This is particularly true of insert molding in which the inserts are particularly expensive and it is worth saving say 7 out of 8 cavities if one is bad rather than discarding the whole shot.

The Solution:

Send a separate Sorting Output / Good Control to the automation (usually a robot) to tell it that each cavity is good.

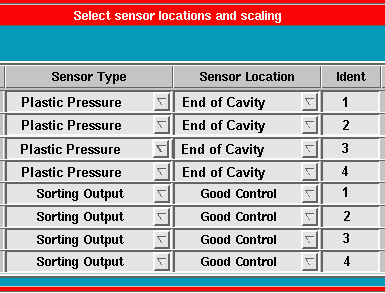

To do this you simply define in “Sensor Locations” several OR2 outputs as Sorting Output / Good Control. Then put a number in each row’s “Id” column to match the cavity number of the pressure sensors.

Then, at the end of each shot, if a certain cavity is not good then the corresponding sorting output (matching id number) will be off. If a machine variable is set up in “Alarm Settings” for sorting and it goes to “Alarm” then all of the individual cavity outputs will be off.

Only assign an id number to the sorting output if you intend to use this multiple output / id matching feature. If not, leave it blank.

Note that all of the actions taken with the individual outputs have the same timing as with the global Sorting Output / Good Control (with blank id column).